Hayashi Sangyo Co.,Ltd.

Square Bottom Bag

- Even for square-bottom bags designed to fit into a cube, our products incorporate ingenuity.

- Home

- Square Bottom Bag

SUITABLY USED AS INNNER BAGS FOR FOOD & MATERIAL

- Clean Plants – ISO9001 & Japan Flexible Packaging Hygiene Association (Ceritication No.194) Certified

- C-MAX Process – Original quality control process which ensures high level of safety.

IDEAL INNER BAG FOR LIQUID&GRANULAR CONTENTS

X SEAL SQUARE BOTTOM INNER BAG (COMMON PRODUCT)

X SEAL is added to the common side gusset bag in order to maintain a stable square bottom shape. X Seal square bottom bag fits the goods container better and makes the square bottom shape stabler and safer. Furthermore, this special structure ensures less waste when pouring out the contents from the bags.

- ※If you use a conventional side gusset bags to pack liquid or granular contents, liquid or granular will enter into the bottom corners of the bag and hard to be taken out. Our square bottom bags largely solved this problem.

DISADVANTAGE OF CONVENTIONAL SIDE GUSSET INNNER BAG

Common side gusset inner bag without our special X SEAL manufacturing process will be easily deformable, especially after packaging liquid or granular contents. The goods will be unstable after packaging due to unfitting with the containers such as carton boxes.

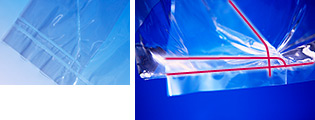

XHN SEAL : IMPROVED VERSION OF X SEAL

XHN SEAL square bottom bag makes a modification, which adds another seal on the basis of X SEAL to disperse stress of the gusset part and prevents the pinholes on edges remarkably.

- ※suitable for packaging liquid and granular contents as a thin container liner.

XTO SEAL : IMPROVED VERSION OF XHN SEAL

A seal shaped like the letter r is added on the basis of X SEAL to distribute stress to the edge parts.

- ※This design is effective for the situation when you want to take out the content of liquid or granular contents with the outer bag together.