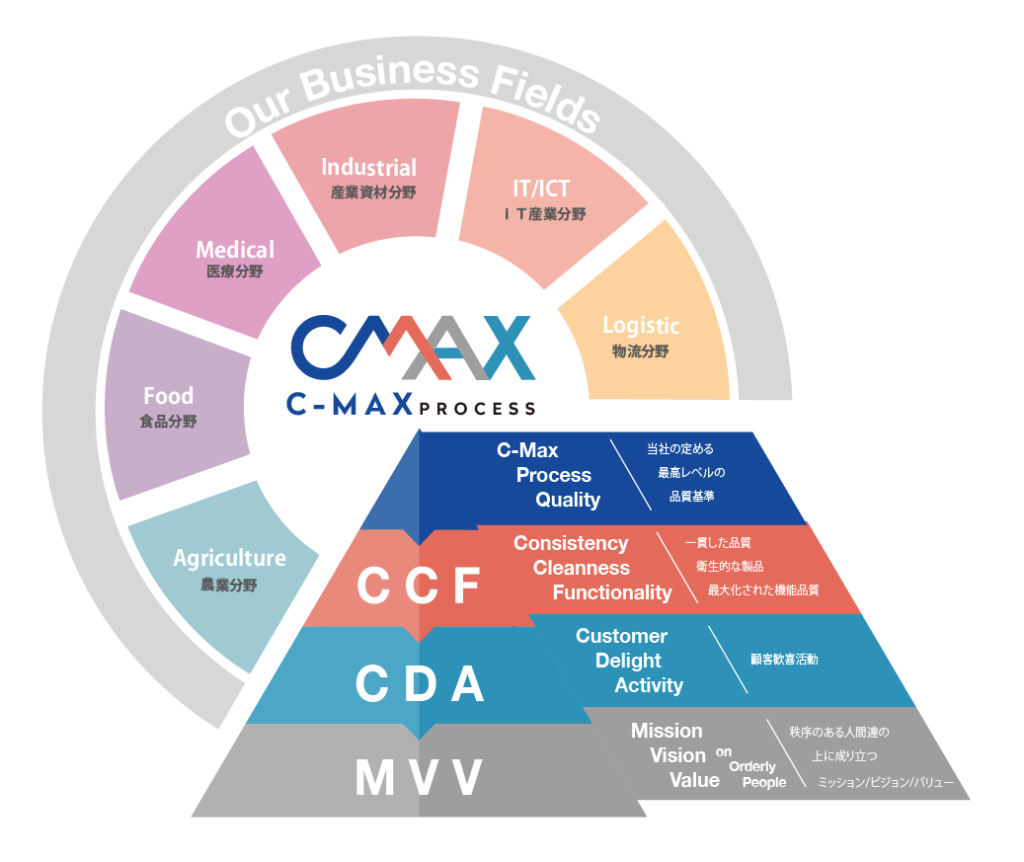

C-MAX Process:Production Environment

The C-MAX Process is our specialized system ensuring top-notch polyethylene packaging materials. It guarantees high functionality and safety. Our rigorous quality checks at every step, from inflation to processing and logistics, meet the strict standards for medical and food applications.

CMP Blown Film Extrusion Plant

Production Environment:

filtering high circulation positive pressure system;

door interlocking system(air shower for cleanroom,door interlock,etc.)

- dust control:NA Class 100,000(measured value during operation: 50,000~90,000)

- insect&rat prevention system/microbial control system

CMP Printing Plant

Production Environment:

filtering high circulation positive pressure system;

door interlocking system(air shower for cleanroom,door interlock,etc.)

- dust control:NASA Class 100,000(measured value during operation: 20,000~90,000)

- insect&rat prevention system/microbial control system

CMP Bag Making Plant

Production Environment:

filtering high circulation positive pressure system;

door interlocking system(air shower for cleanroom,door interlock,etc.)

- dust control:NASA Class 100,000(measured value during operation: 20,000~90,000)

- insect&rat prevention system/microbial control system

C-MAX Process:Management Features

Software Management (excerpt from Management Standards)

- Hygiene management of workplaces

- Hygiene management of operators

- Safety and hygiene management of manufacturing process

- Safety and hygiene management of raw materials,intermediate products and final products

- Safety and hygienic standards for products

- Cleaning and management of workplaces(inside&outside) and bathrooms

- Management of positive pressure

- Management of falling bacteria at workplaces

- Dust management at workplaces

- Processing method for abnormality occurring relating to the product safety and hygiene

- Hygiene management record,etc.